Quality easyOSP FTTH Drop Cable at Affordable Cost.

To bring end-to-end optimal solutions for each and every infrastructure configuration, easyOSP provides drop cables engineered for specific applications as well as versatile drops, developed to adapt to various installation environments.

Our optical drop cabling offer is CPR compliant and developed to meet all type of network configurations: for duct, façade and overhead lines outside plant or indoor FTTH roll-outs.

Built with first-choice fiber and cable sheath materials, easyOSP FTTH drop cables are developed as future-proof solutions for ultrafast broadband fiber networks.

Depending on the selected model, cables can be laid by pulling or pushing, ran inside occupied ducts or simply laid alongside baseboards by stapling or gluing.

These optical drops enable outside access network connections on short distances.

The outdoor-indoor transition is smoothly realized without cable cutting, thus no splice is needed.

Thanks to its 2.6x1.8mm dimensions, the LM7 or LM7N suits also to installation into already occupied ducts.

easyOSP FTTH Drop Cable is cost-effective, space-saving solution with excellent quality.

Special low-bend-sensitivity fiber provides high bandwidth and excellent communication transmission property

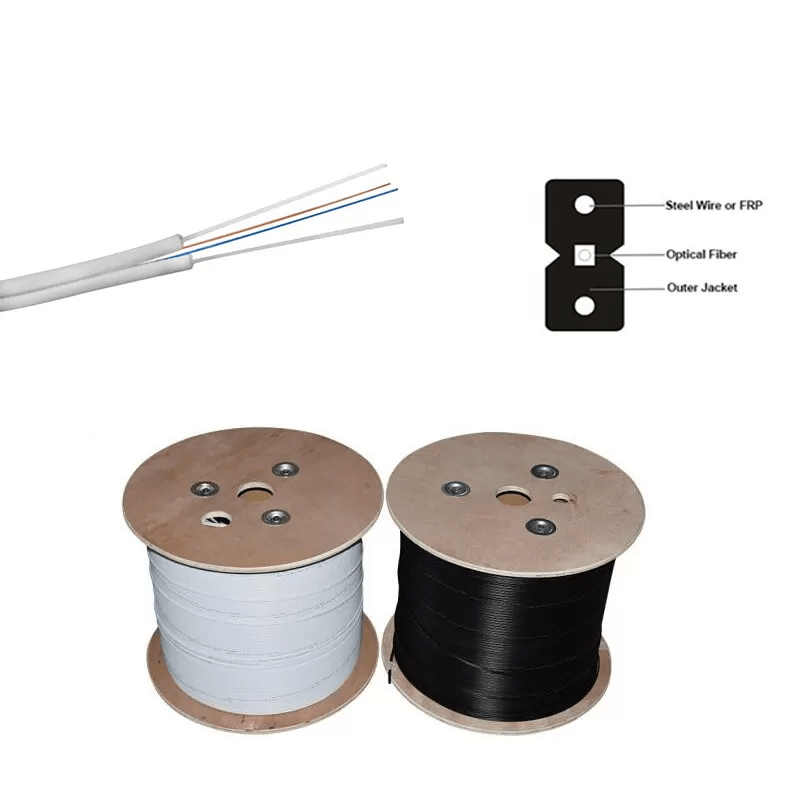

Two parallel strength members ensure good performance of crush resistance to protect the fiber

Novel notch design for easy stripping, and easy connection without splicing or with splicing, simplify the installation and maintenance

Low purchasing and construction costs.

Compact and lightweight, and high practicability

It reduces the amount and density of the smoke, which makes exiting a space easier for occupants as well as increases the safety of firefighting operations.

Here below are some common questions on FTTH Drop Cables. If you have other questions, feel free to contact us via [email protected]

Drop cable as an important part of FTTH network forms the final external link between the subscriber and the feeder cable. As it is used in outdoor, drop cable shall have a minimum pull strength of 1335 Newtons according to the industry standard. Drop cables are available in many different types. The following part introduces three most used drop cables divided according to the cable structure.

| Parameter | Unit | Value |

| Crush (short term) | N/100 mm | 500 |

| Strength member | FRP | |

| Storage temperature | °C | -20 to 60 |

| Installation temperature | °C | -5 to 50 |

| Operating temperature | °C | -20 to 60 |

| Primary buffer diameter | µm | 250 |

| Fiber count | n | 1 to 4 |

| Nominal outer diameter | mm | 2.0 x 3.0 ± 0.2 |

| Nominal weight | kg/km | 7 |

| Maximum tensile load | N | 80 |

| Minimum bend radius (installation) | mm | 44 |

| Minimum bend radius (installed) | mm | 25 |

| Jacket material | LSZH | |

| Drum Length | m | 2 |

Drop cable as the final connection from the fiber optic network to customer premises also plays an important role. Thus, finding a flexible, efficient and economical drop cable connectivity method becomes a crucial part of broadband service. Whether to use a fiber optic connector, which can be easily mated and un-mated by hand or a splice, which is a permanent joint?

Generally, splice is recommended for drop cables in the places where no future fiber rearrangement is necessary, like a greenfield, new construction application where the service provider can easily install all of the drop cables. Fiber optic connector is appropriate for applications which flexibility is required, like ONTs which have a connector interface.

For splice, there are two methods, one is fusion splicing, the other is mechanical splicing. Fusion splicers have been proved to provide a high quality splice with low insertion loss and reflection. However, the initial capital expenditures, maintenance costs and slow installation speed of fusion splicing hinder its status as the preferred solution in many cases. Mechanical splicing is widely used in FTTH drop cable installation in countries, as a mechanical splice can be finished in the field by hand using simple hand tools and cheap mechanical splicer (showed in the following picture) within 2 minutes. It’s a commonly used method in many places, like China, Japan and Korea. However, in US mechanical splicing is not popular.

For fiber optic connector, there are two types connector for drop cable connection.

If you have no limits in cost and want high performance termination in a time-save way, pre-terminated drop cable could be your choice. Many factories can provide you customized drop cables in various fiber types, fiber optic connector and lengths.

Multi Tube Steel Armored cables are a strong, Industrial grade FO cable with strong Mechanical protection. With an external PE Jacket, the cable is perfect for Direct Burial applications and offers optimum protection against UV. With each core capable of holding up to 12 cores, Multitube FO Cables can accommodate a maximum of 288 Fibers and can be built for OS2, OM1, OM2, OM3, OM4 or OM5 depending on client requirement.

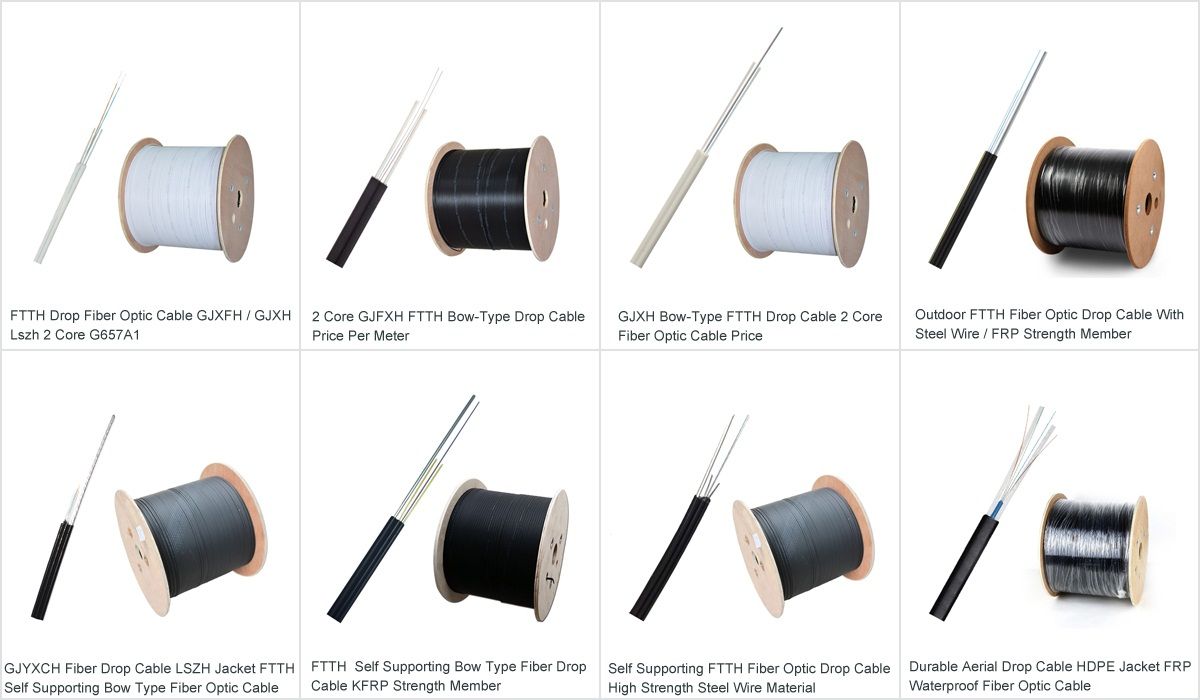

We provide the most used types of drop cables, see the picture below.

Various types of FTTH drop

cables

+ 86 138 17004898

Building C, No.89 Hetai Road, Baiyun District, Guangzhou, China, 510440