Quality easyOSP Fabric Innerducts at Affordable Cost.

Fabric innerducts are designed to cables placed within, reducing cable pulling tensions while increasing cable capacity by as much as 300%. minimizing the wasted space and saving cost.

3 Cell Fabric Innerduct is the most used type in fiber networks.

You can customize various Fabric Cable Inner Duct

The usual length is 2000m with wooden drum.

Installers and Network Engineers can finish conduit installation time in half

Increase the untilization rate of communication pipeline up to 50%-60%

Save the pipeline resource and reduce investment for fiber cable installation

easyOSP Fabric Innerduct maximizes your conduit and network

Tensile strength of braided sub-pipe is more than 1 ,000 kg

Braided sub-pipe has no bending memory and doesn' t curl like PE sub-pipe;

The textile sub-pipe has high chemical inertness and could be exposed to the severe underground environment for a long time with design life of 50 years.

Braided sub-pipe is not twisted during the laying and could be bent freely

The friction coefficient of braided sub-pipe is low and prevents the friction between cables

Low requirement on construction site, especially in downtown area;

Here below are some common questions on Fabric Innerduct, if you still have questions, Please feel free to contact us via [email protected]

An innerduct for segregating cables in a conduit is provided wherein the innerduct is constructed from one or more strip-shaped lengths of a woven textile fabric and configured to provide multiple longitudinal compartments for the cables, and the textile fabric has a warp of monofilament yarn ends and a filling of a combination of monofilament and multifilament yarn picks, with the multifilament yarn picks being multiple-inserted yarns.

Fabric Innerduct is the only flexible fabric innerduct system designed specifically for the network construction industry. The unique fabric construction greatly reducing the wasted space associated with rigid innerduct.

Inflatable type culvert sealing system, which have been widely used in the design of underground culvert constructions in the industries of electric system, telecommunications, port, urban construction, rail transportation and so on. Provide a clean and dry operating environment to cables and other electrical equipment after installation, improve the degree of protection, and reduce the works of cleaning up sludge and stagnant water in the manual well before the maintenance works.

The textile sub-tube has no bending memory; it does not curl like a PE sub-tube;

The textile sub-tube will not be kinked during laying and can be bent freely during laying;

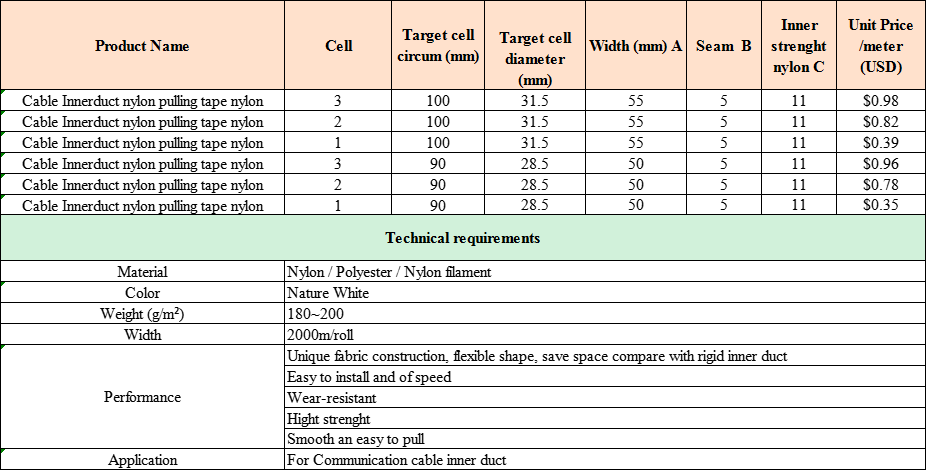

The textile sub-tube is preset with high-strength draw tape in each hole, and the laying of the cable does not need to be through-hole, and the laying is more convenient and quick;

The construction site requirements are very small, especially suitable for busy districts.

The breaking strength is above 1000 kg;

Textile tube melting point = 215。C, while HDPE sub-tube = 110。C;

The thermal expansion and contraction rate of the textile tube is 1/7 of that of the HDPE sub-tube;Prevents wear between cables.

The textile sub-tube has high chemical inertness and can be exposed to a harsh underground environment for a long time. The design life is 30-50 years, and the life of the PE sub-tube is only 15 years.

Two holes in the textile sub-tube product family, three holes will be preset with different colors of the draw tape for the differentiation during construction;

The textile sub-tube will print the meter mark when it leaves the factory to prevent unnecessary waste during construction;

When the textile sub-tube is delivered from the factory, it will be labeled according to the customer's needs, suchasA, B, C A1, A2, A3, etc., used to distinguish the multiple textile sub-tubes in the pipeline, to facilitate the maintenance of the line.

The textile sub-tube can reach 30-50 years underground. Ordinary HDPE sub-tubes will form slag due to aging in the ground for a long time, and become a blockage in the pipeline. The textile sub-tube solves this problem from the design concept and has high environmental protection for the pipeline.

| Fabric Innerduct Item # | Tensile strength |

| FZ8638-1 | >760kg |

| FZ8638-2 | >1440kg |

| FZ8638-3 | >2120kg |

| FZ6428-1 | >592kg |

| FZ6428-2 | >1104kg |

| FZ6428-3 | >1616kg |

| FZ5222-1 | >496kg |

| FZ5222-2 | >900kg |

| FZ5222-3 | >1300kg |

| FZ4418-1 | >432kg |

| FZ4418-2 | >784kg |

| FZ4418-3 | >1136kg |

| FZ3614-1 | >368kg |

| FZ3614-2 | >650kg |

| FZ3614-3 | >940kg |

| FZ3212-1 | >332kg |

| FZ3212-2 | >584kg |

| FZ3212-3 | >836kg |

| FZ2810-1 | >304kg |

| FZ2810-2 | >528kg |

| FZ2810-3 | >752kg |

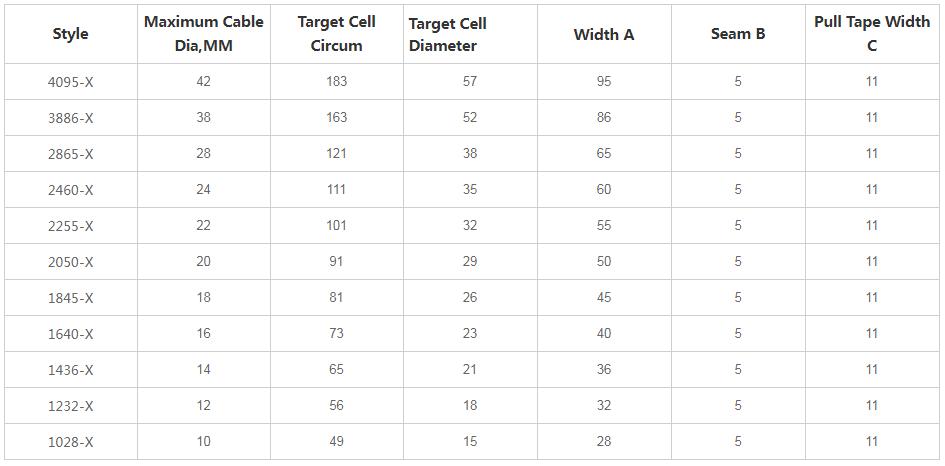

Most Customers who are interested in Fabric Innerduct Send inquiries for the below common items, If you are also looking for similar Fabric Innerducts for your outside plants, You can refer to the below price table.

For more assistance, Please feel free to contact us to get a quick quote or discount.

+ 86 138 17004898

Building C, No.89 Hetai Road, Baiyun District, Guangzhou China, 510440